Comparison of pneumatic ball valve and pneumatic butterfly valve

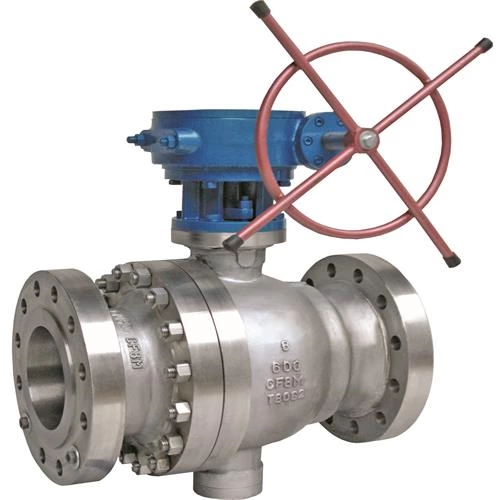

The pneumatic ball valve is a ball that is opened and closed by rotating the ball 90° around the axis of the valve stem. The pneumatic ball valve is mainly used to cut, distribute and change the flow direction of the medium on the pipeline. The pneumatic ball valve designed as a V-shaped opening also has a good flow regulation function. Unlike the pneumatic ball valve, the pneumatic butterfly valve is a valve that opens and closes and adjusts the fluid passage by reciprocating about 90° with a disc type opening and closing member.

Pneumatic ball valve features: blockage and secretion: When the valve is closed, the valve seat on the upstream and downstream sides blocks the liquid, and the accumulation of the cavity in the valve body can be secreted by the secretion device. Automatic pressure relief structure: When the pressure in the side cavity is abnormally added, the medium cavity medium can automatically push pressure on the valve seat according to its own thrust, and then ensure the safety of the valve. Reliable sealing of the valve stem: the valve stem is selected as a bottom-loading structure with an inverted seal. The sealing force of the inverted seal increases with the increase of the medium pressure, so that the valve stem can be reliably sealed, and when the valve stem is abnormally boosted, The valve stem will not be ejected. Fireproof structure: According to the working conditions and the needs of users, the ball valve can be planned as a fireproof structure. Anti-static structure: When the valve is operated, due to the friction between the ball and the valve seat, the electrostatic charge of the cattle will occur and accumulate on the sphere. In order to prevent the occurrence of static sparks, an electrostatic device is placed on the valve to accumulate on the sphere. Charge derivation.

The characteristics of the pneumatic butterfly valve: the circular butterfly plate with the rolling of the valve is opened and closed, and the pneumatic valve that completes the activation action is mainly used as the shut-off valve. According to the structural characteristics of the pneumatic butterfly valve, it can also be planned to have the function of scheduling or segment valve and scheduling. Nowadays, the application of butterfly valves on low-pressure large and medium-diameter pipes is constantly added. In fact, many devices have pneumatic butterfly valves, especially on the pipeline, but we should never underestimate it. However, many people are the first to hear about pneumatic butterfly valves, but they don't understand their advantages. But don't worry about the shortcomings of the pneumatic butterfly valve.

The pneumatic ball valve is mainly used in the pipeline to cut off the speed, distribute and change the flow direction of the medium. Pneumatic ball valve is a new type of valve that has the following advantages:

1. The fluid resistance is small, and the resistance coefficient is equal to the pipe length of the same length.

2. Simple structure, small size and light weight.

3. It is close and reliable. The sealing surface material of the ball valve is widely used in plastic and has good sealing performance. It has also been widely used in vacuum systems.

4, easy to operate, open and close quickly, from full open to full off as long as rotated 90 °, easy to control over long distances.

5, easy maintenance, pneumatic ball valve structure is simple, the sealing ring is generally active, disassembly and replacement are more convenient.

6. When fully open or fully closed, the sealing surface of the ball and the valve seat is isolated from the medium. When the medium passes, it will not cause erosion of the sealing surface of the valve.

7, a wide range of applications, from small to a few millimeters, up to a few meters, from high vacuum to high pressure can be applied.

8. Because the power source of the pneumatic ball valve is gas, it is generally 0, 2-0, 8MPa pressure, which is relatively safe. If the pneumatic ball valve leaks, the gas can be directly discharged compared with the hydraulic and electric motors, and it has no pollution to the environment and has high safety.

9. Compared with manual and turbo rotating ball valves, pneumatic ball valves can be configured with large diameters. (Manual and turbo rotating ball valves are generally below DN300 caliber, pneumatic ball valves can reach DN1200 caliber.)

The disadvantages are as follows:

1. Its adjustment performance is worse than that of the shut-off valve, especially the pneumatic valve;

2. Because the main seat seal material of pneumatic ball valves is Teflon, it is inert to almost all chemicals. However, the physical properties of Teflon, including higher coefficient of expansion, sensitivity to cold flow, and poor thermal conductivity, require that the design of the seat seal must be centered around these characteristics. When the sealing material is hardened, the reliability of the seal is destroyed. Moreover, PTFE has a low temperature resistance and can only be used at less than 180 °C. Above this temperature, the sealing material will age. If you want to allow long-term use, it is generally recommended to use at 120 °C; the advantages of pneumatic butterfly valve: 1, the opening and closing is convenient, labor-saving, small fluid resistance, and can be operated frequently. 2, the structure is simple, small size and light weight.

3, able to transport mud, the least amount of liquid accumulated in the pipe mouth.

4, under low pressure, can complete an outstanding seal.

5, good conditioning performance.

Disadvantages:

1. The sealing performance of pneumatic butterfly valve is relatively poor compared with pneumatic ball valve and pneumatic valve, so it is not used for sealing requirements;

2. Due to the structure of the pneumatic butterfly valve and the limitation of the sealing material, it is not suitable for use in high temperature and high pressure piping systems. The general working temperature is below 300 ° C, below PN40;

3. The flow adjustment range of the pneumatic butterfly valve is not large. When the opening is up to 30%, the flow rate reaches nearly 95%; the pneumatic butterfly valve and the pneumatic ball valve are not allowed to adopt the valve with the diameter contraction under certain working conditions. This aspect is to reduce the resistance loss of the pipeline, and on the other hand to avoid obstacles to the mechanical cleaning pipeline after the diameter shrinkage.