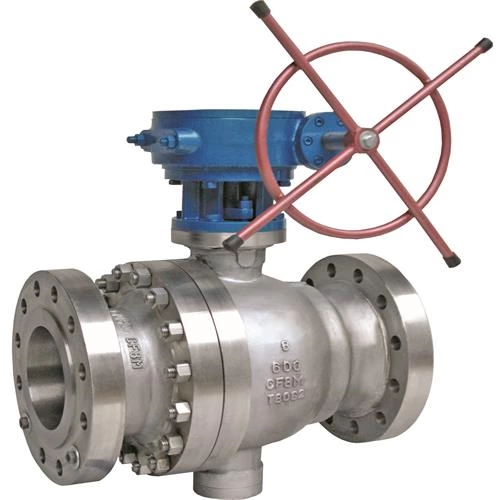

Electric Gate Valve

- Size Range

- NPS 2′′~NPS 48′′ DN50~DN1200

- Temperature Range

- -196°C~+600°C

- Pressure Rating

- CLB150~CL2500 PN10~PN420

Specification parameters

| Name | Electric gate valve |

| Size | NPS 2′′~NPS 48′′ DN50~DN1200 |

| Pressure | CLB150~CL2500 PN10~PN420 |

| Temperature | -196°C~+600°C |

| Application | Water, sewage, construction, petroleum, chemical, food, pharmaceutical, textile, electric power, shipbuilding, metallurgy, energy systems, etc. |

| Body Material | carbon steel, stainless steel, alloy steel |

Design Specification:

| Design Standards | API 600, ASME B16.34, GB/T 12234 |

| Structure length | ISO14313/API 6D, ASME B16.10, GB/T 12221, DL/T 53 |

| Connection Standard | ASME B16.5, ASME B16.47, ASME B16.25, GB/T 9113, JB/T 79, HG/T 20592, DL/T 531, JB/T3595, JB7490 |

| Pressure test | API 6D, API 600, API 598, GB/T 13927, GB/T 26480, JB/T 9092, JB/T3595 |

| pressure and temperature rating | ASME B16.34, GB/T 12224 |

Product introduction

The electric gate valve is a kind of gate valve. The driving method of the electric gate valve is electric actuator. The connection method is flange type, welded type and clip type.

Structural characteristics of electric gate valve

1. The ram has two sealing faces. The most common is that the two sealing faces of the ram form a wedge shape, and the wedge angle varies with the valve parameters, usually 5°.

2. The sealing principle of the electric gate valve is achieved by the tight combination of the two sealing faces on the wedge gate and the two sealing faces on the valve body when wedged.

3. Electric gate valve, American standard wedge valve can be divided into open gate valve (lifting gate valve) and dark gate valve (rotating rod gate valve) according to the different ways of opening and closing the valve stem.

4. According to the different structure of the ram, the electric gate valve can be divided into an elastic ram gate valve and a rigid ram gate valve.

5. The valve body is cast and molded, the valve body and the valve cover are bolted, and the middle flange is sealed with a wound gasket. When the customer has special requirements, the metal ring can also be used for connection.

6. The channel is smooth and the flow coefficient is small. The sealing surface is less scoured and eroded by the medium.

7. The sealing surface is made of alloy steel or hard alloy, which has good wear resistance and scratch resistance.

8. It adopts flexible graphite packing, which is reliable in sealing and light and flexible in operation.

9, the flow direction of the medium is not limited, no disturbance, no pressure reduction.

10. The shape is simple, the structure length is short, the manufacturing process is good, and the application range is wide.

Get in Touch

Contact Us

Dongou Industrial Zone,Oubei Town,YongJia, WenZhou City,ZheJiang Province P.R China